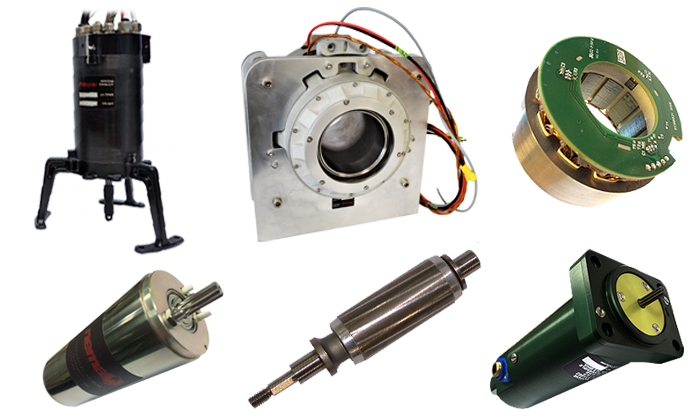

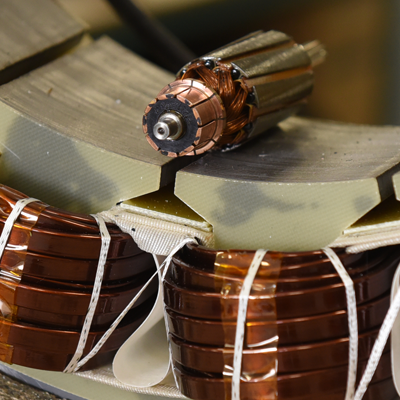

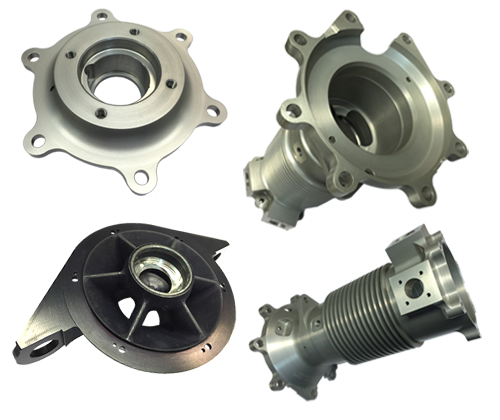

We design and manufacture a diverse range of rotating electrical motors and generators many of which are used in flight critical and defence applications.

Our manufacturing techniques range from skilled hand operations to semi-automatic allowing for prototyping or full rate production.

| Parameter | Min Value | Max Value | Units |

| Power | 0.010 | 200 | kW |

| Voltage | 3.3 | 1080 | V |

| Speed | Slow Crawl | 183,000 | RPM |

| Size - Outer Diameter | 10 | 500 | mm |

| Ambient Temp | -90 | 250 | °C |