Innovating Electromagnetic Technology

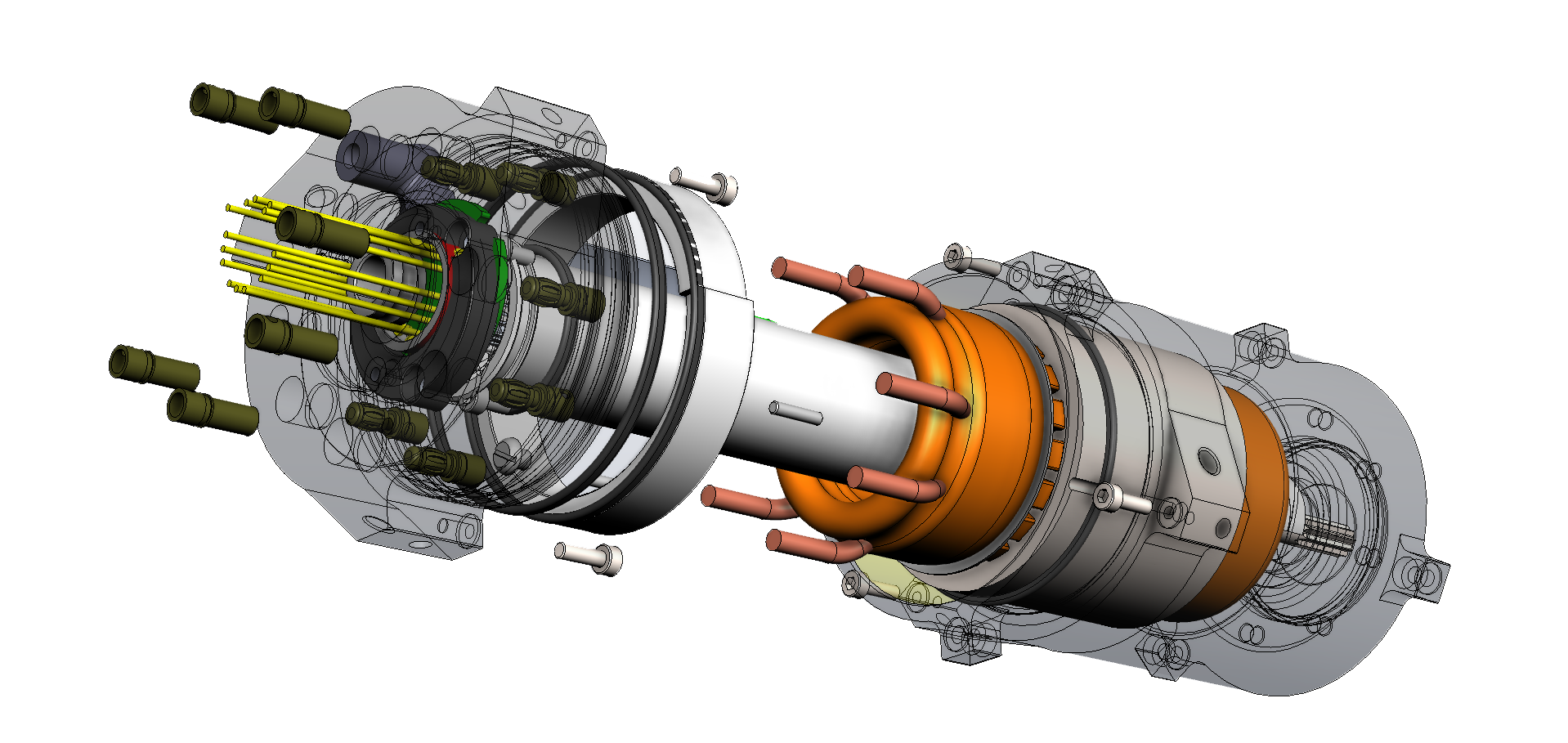

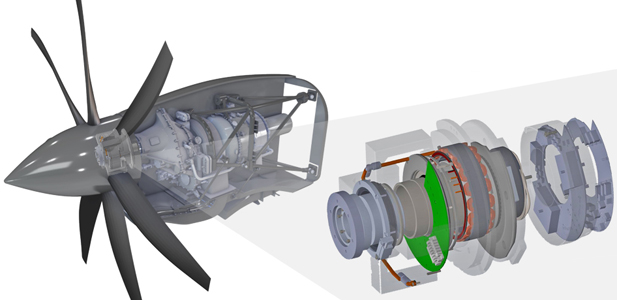

NEMA specialise in designing, reverse / obsolescence engineering, building and supplying technically innovative, high speed motors

and motor generators to the aerospace and defence sectors. Our motors and generators are used in many electro-mechanical actuation systems and

meet customer specifications across a wide range of applications and challenging environments.